Using biogas technology to solve the disposal issues surrounding latrine waste

Practical Action

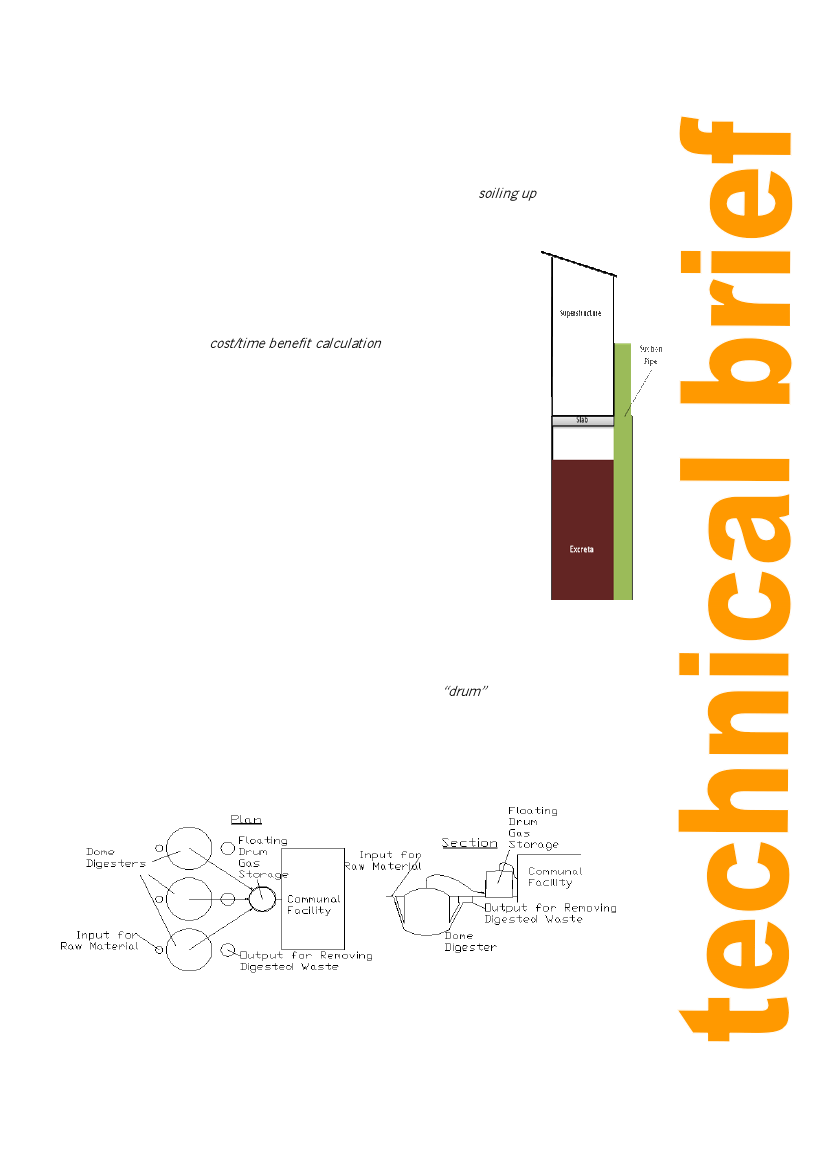

operational life of the pit. Dismantling often required when emptying a pit. A solution

proposed is to fit an in-situ pipe to the pit that has an exit outside the super structure (Figure

4). This addition will limit the disruption caused by emptying as well as making the whole

process more hygienic because the hose will no longer have to be dropped into the faeces. The

addition will also help deal with the problems regarding viscosity and soiling up in pits (3)

because emptying will happen from the bottom and water can be added through the pipe to

decrease the viscosity.

Haulage: for sustainability reasons and to limit costs the push is to combine

the system with manually operated emptying technologies (Boot N., 2006).

These technologies are also more feasible in urban settings where access is an

issue for vacuum pumps. When using these technologies it is not the distance

from the latrine to the disposal point that is the defining factor but the time it

takes. In this situation a cost/time benefit calculation should be used working

backwards from the costs that must be covered for the system to work which

will give the number of empties per day required. Using this information and

the average working day a suitable haulage distance can be calculated.

Disposal: essentially the placement of the digester which is governed by three

main factors:

• Space and land tenure; in slum areas space is sparse and they live on

land they do not own so improving sanitation facilities is not high on

their priority list

• Not in my back yard (NIMBY); people do not want waste dumped

where they live however this is a very context specific area

• Use of the gas; whether it be a communal facility or private household

Logistic issues also affect the placement as outlined above.

Treatment: there are essentially two main issues regarding treatment.

The first is problems surrounding pressure of the gas. One solution

would be to ensure that the digester is correctly maintained. Another

physical solution, highlighted by Kossmann (1999), is the use of a

Figure 4: A diagram

conveying the use of an in

situ pipe.

separate gas holder. Floating drum digesters allow the user to alter the

pressure of the gas by applying weight and pushing the moving “drum” down. Research has

highlighted maintenance issues surrounding these digesters and that fixed dome digesters

provide better results. Therefore a possible solution is to take the benefits from both

technologies and use them to their full advantage by using the fixed dome design for the

batched digester setup while connecting a floating drum design in series to act as storage, so

when/if the user does experience pressure complications they can apply an amount of weight

to the top of the drum and increase the pressure.

Figure 5: Possible digester setup to deal with pressure issues.

The other treatment issue that needs to be assessed is the concentration of nitrogen in the

feedstock. Mang & Li (2009) describes how urea from urine will be toxic to the bacteria (self-

intoxification) involved in digestion. In practice, Mang & Li(2009) stress it is important to

3